Why Choose a Pre-Engineered Tarca Patented Track Crane System?

For starters, we offer the Industry’s Best Warranty 2 Years on all Crane Systems. Designed for Crane Applications

Crane Systems specify which beam to use for each application. We do not “Suggest” or “Recommend” any materials be used. Ease of Installation

All components are built and assembled with jigs and fixtures which ensure easy installation. Improved Performance

Tarca® Systems are designed to be superior to I-beam cranes in strength, durability, and consistency. Versatility

ASE offers a complete line of cranes to meet your individual needs. Safety

All cranes are pre-engineered for powered hoist operation with an impact factor of 15%.

Tarca® Track For Durability and Strength

These pre-engineered crane systems are built using our unique patented Tarca® Track, which continues to be the benchmark of the overhead material handling industry. Its three piece welded construction is a compound section of a mild steel top flange and web and a specially rolled high-carbon steel lower rail. Tarca® systems are characterized by consistently straight rail sections and durable, high quality Tarca® components. Our Tarca® systems offer unmatched versatility, durability, and ease of installation. Why Tarca® Track Over Structural Steel Track?

A structural I-beam is rolled from soft, mild steel according to fairly loose steel mill tolerances. Its beveled flange prevents wheels from making balanced contact, causing uneven wear and a shortened track life. Tarca’s unique Patented Track, with its special raised tread and high carbon track, is superior to I-beams in strength, durability and consistency. Our exclusive rails permit the use of:

- Underhung carriers operating on a single straight, curved or inclined track

- Underhung cranes operating on two or more straight track runways.

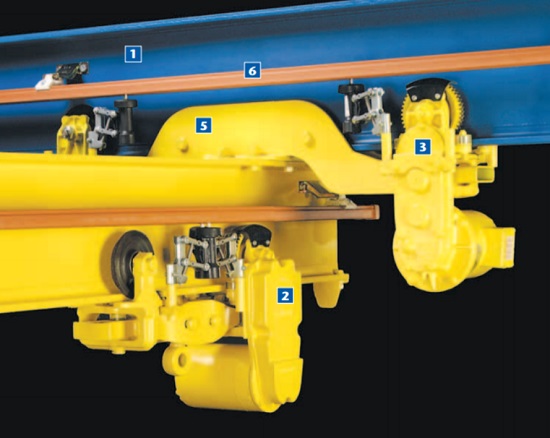

Crane Components

Tarca® Rail

Tarca® Track features specially rolled high-carbon alloy steel rail with raised treads welded to a steel flange and web. Tarca is designed to provide maximum spanning capability for heavy loads while minimizing the weight of required material. Its material properties resist peening and assure a longer operating life than ordinary track designs.

Carriers (Trolleys)

- Trolley carriers provide the connection between the lifting device and the bridge. Our carriers are designed for years of peak performance:

- The wheel base is proportioned for smooth, vibration-free carrier operation.

- Swiveling yoke provides unmatched performance through curves and switches on monorail systems, contributing to longer track life.

- Precision manufacturing and specially designed wheels assure consistent wheel to rail contact.

- The extensive variety of our carriers provides endless flexibility to tackle any application.

- Manually driven carriers are also available.

Motorized Drives

- These drives motorize the travel of carriers and end trucks. We offer:

- A gear driven drive, the best choice for most applications.

- A belt driven drive designed to be a lower cost alternative to the gear driven drive.

- A tractor driven drive for specialty systems, such as pulling loads up a slope or for use in wet conditions.

- Our drives were specially designed to make them long wearing and easy to service.

- Guide rollers equipped with anti-friction bearings align wheels on track for easy movement.

- Split frame construction for easy removal and re-installation

Hanger Assemblies

|

End Trucks

End truck with drive for motorized travel on runway Gorbel® end trucks provide the connection between the bridge and runway. These rugged end trucks give you smooth, easy travel with little or no maintenance. One advantage of our end trucks are their wheels. While other manufacturers have fixed wheels on their end trucks, our articulating wheels allow for irregularities in track and runways. End trucks can also be manually driven.

Electrification Options (Brackets, Collector Shoe and Bar)

|

End Stops

End stops are required and must be provided at the ends of the carrier or trolley travel on bridges and at the end of crane travel on runways. Our end stops are unique in that they strike the end of the load bar, rather than the wheels. This prevents the wheels from absorbing the force of the load and reduces the areas of wear. We offer standard wheel end stops for lighter applications and rubber, spring or hydraulic bumpers for higher speed 5 conditions.

Have Question/Query? Fill this Form to send us a message, we will get back to you shortly!